View Locations

Locations

Atlantic

1800 Albertson Road

High Point, NC 27260

Phone: 336.882.0186

Industry Rich Southeast Region

As our largest Division encompassing a Casting facility and a Precision Components Machining facility, Atlantic Division is located in the industry rich Southeast region of the United States. From this location we service not only the SE region, but also most of Mexico’s industry regions.

Casting Facility Capabilities

Our Casting operation includes 13 high pressure aluminum die casting machines ranging from 900-1600T. We offer several different alloys with the use of stack melt systems that optimize energy consumption and allow for manufacturing flexibility. Our finishing capabilities include vibe and/or shot blasting and finish machining at our Precision Components operation.

Precision Components Machining Capabilities

The Precision Components Machining operation employs over 18 CNC machining centers to provide fully machined and leak tested aluminum casting applications. By having the casting and machining operations within minutes of one another, we can effectively run production and keep a closed loop feedback process from machining back to casting. This is a critical element in managing and producing leak tight, porosity sensitive applications.

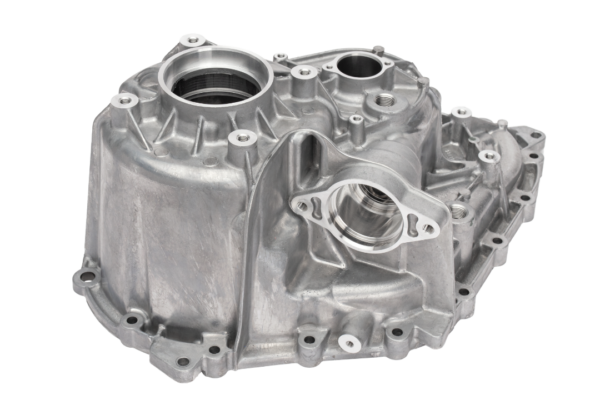

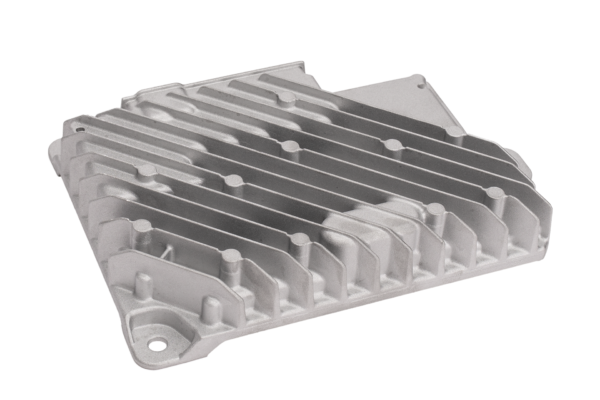

Parts

Aluminum die castings offer several advantages including near net shape, strength, and weight reduction. The Atlantic Division has experience delivering all of these benefits with special emphasis on complex, leak tight housings and covers, thin walled electrical enclosures, brackets, and many other demanding applications.

Metals

The Atlantic Division casts two different types of alloys: 380 and 413. Our high efficiency furnaces help deliver the right metal for your high pressure aluminum die castings. If you have another alloy you’re designing for, contact us and we can discuss adding that alloy to meet your needs.

Facility Capabilites

Casting Facility Capabilities

Our Casting operation includes 13 high pressure aluminum die casting machines ranging from 900-1600T. We offer several different alloys with the use of stack melt systems that optimize energy consumption and allow for manufacturing flexibility. Our finishing capabilities include vibe and/or shot blasting and finish machining at our Precision Components operation.

Machining Capabilities

Precision Components Machining Capabilities

The Precision Components Machining operation employs over 18 CNC machining centers to provide fully machined and leak tested aluminum casting applications. By having the casting and machining operations within minutes of one another, we can effectively run production and keep a closed loop feedback process from machining back to casting. This is a critical element in managing and producing leak tight, porosity sensitive applications.

Parts

Parts

Aluminum die castings offer several advantages including near net shape, strength, and weight reduction. The Atlantic Division has experience delivering all of these benefits with special emphasis on complex, leak tight housings and covers, thin walled electrical enclosures, brackets, and many other demanding applications.

Metals

Metals

The Atlantic Division casts two different types of alloys: 380 and 413. Our high efficiency furnaces help deliver the right metal for your high pressure aluminum die castings. If you have another alloy you’re designing for, contact us and we can discuss adding that alloy to meet your needs.

Mid-State

7750 South Division

Grand Rapids, Michigan 49548

Phone: 616.455.4010

Founding Facility

Think zinc and think Cascade Die Casting Group’s Mid-State Division. As the founding facility in our portfolio, we have been servicing the industry for over 46 years from this operation. Coupled with our Precision Components finishing facility, we can offer world class decorative applications, functional applications and everything in between.

Casting Facility Capabilities

Our casting operation utilizes 8 high pressure zinc die casting machines ranging from 600-1000T. Coupled with our investment in robotics we drive operational speed that reduces cost.

Precision Components Finishing Capabilities

The Precision Components finishing facility has the capability to polish and buff for Class A, decorative applications. By controlling both the casting and finishing operations, and with our valued supplier partners who can paint or plate the prepared casting, Cascade Die Casting Group offers you a Tier 1 supplier relationship so that you can focus on your business. We will manage the entire supply chain so that you have peace of mind and the right products, right the first time.

Parts

Our foundation was functional zinc die casting applications and we’ve strategically grown to offer both functional and Class A zinc die castings. No matter what the appearance demands of your zinc casting needs, we can offer a cost competitive solution.

Metals

Whether it’s strength or decorative design driven, we have the zinc alloy for your needs with our Z3, Z5 and Z8 capabilities.

Facility Capabilites

Casting Facility Capabilities

Our casting operation utilizes 8 high pressure zinc die casting machines ranging from 600-1000T. Coupled with our investment in robotics we drive operational speed that reduces cost.

Finishing Capabilities

Precision Components Finishing Capabilities

The Precision Components finishing facility has the capability to polish and buff for Class A, decorative applications. By controlling both the casting and finishing operations, and with our valued supplier partners who can paint or plate the prepared casting, Cascade Die Casting Group offers you a Tier 1 supplier relationship so that you can focus on your business. We will manage the entire supply chain so that you have peace of mind and the right products, right the first time.

Parts

Parts

Our foundation was functional zinc die casting applications and we’ve strategically grown to offer both functional and Class A zinc die castings. No matter what the appearance demands of your zinc casting needs, we can offer a cost competitive solution.

Metals

Metals

Whether it’s strength or decorative design driven, we have the zinc alloy for your needs with our Z3, Z5 and Z8 capabilities.

Great Lakes

9983 Sparta Avenue

Sparta, Michigan 49345

Phone: 616.887.1771

Heartland of the Midwest

Our Great Lakes Division is located in the heartland of the Midwest and provides easy access to transportation routes that support our nations manufacturing rich areas. Our footprint also offers us access to world class tooling sources and supplier partners that enhance our overall die casting offering.

Casting Facility Capabilities

Our casting operation includes 13 high pressure die castings machines ranging from 900-1600T and with our recent plant expansion we’re poised to add additional die casting machines for your future aluminum die casting applications. One of our key strengths is our fully automated cells that offer the most cost effective approach to cast and trimmed applications that don’t need finish machining.

Parts

As the largest supplier of mirror bases and brackets to the automotive industry, our experience with complex shapes and multi-slide tooling designs is second to none. For high volume applications, you need to drive cost optimization through multi-cavity tooling approaches that maximize output – the Great Lakes Division had led the industry in successfully developing and launching these aluminum die casting applications.

Metals

The Great Lakes Division offers two alloys, 380 and 360. The industry’s most cost-effective alloy, 380, and the corrosion-resistant 360, coupled with the use of high-efficiency stack melt systems, allow the Great Lakes Division to offer industry-proven alloys that blend strength, corrosion resistance, and cost optimization.

Facility Capabilites

Casting Facility Capabilities

Our casting operation includes 13 high pressure die castings machines ranging from 900-1600T and with our recent plant expansion we’re poised to add additional die casting machines for your future aluminum die casting applications. One of our key strengths is our fully automated cells that offer the most cost effective approach to cast and trimmed applications that don’t need finish machining.

Parts

Parts

As the largest supplier of mirror bases and brackets to the automotive industry, our experience with complex shapes and multi-slide tooling designs is second to none. For high volume applications, you need to drive cost optimization through multi-cavity tooling approaches that maximize output – the Great Lakes Division had led the industry in successfully developing and launching these aluminum die casting applications.

Metals

Metals

The Great Lakes Division offers two alloys, 380 and 360. The industry’s most cost-effective alloy, 380, and the corrosion-resistant 360, coupled with the use of high-efficiency stack melt systems, allow the Great Lakes Division to offer industry-proven alloys that blend strength, corrosion resistance, and cost optimization.